Dyna-Tek has introduced its first Semi-Permanent Mold Release Coatings for EPDM Rubber Molding with game-changing results for manufacturers striving for greater production efficiencies, improved quality of the molded part’s appearance, and reduced application costs.

Dyna-Tek has introduced its first Semi-Permanent Mold Release Coatings for EPDM Rubber Molding with game-changing results for manufacturers striving for greater production efficiencies, improved quality of the molded part’s appearance, and reduced application costs.

EPDM (ethylene propylene diene monomer rubber) rubber products is a top choice for manufacturers producing products which need great resistance to environmental conditions including high temps up to 180° C/356° F, UV/Sunlight and ozone.

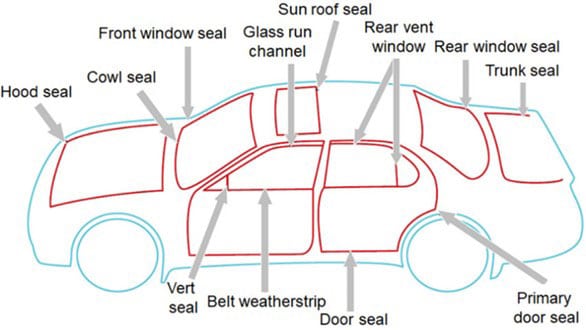

Common Production Applications

- Where an air-tight seal is needed such as freezer/refrigerator seals, industrial respirators, O-rings, and electrical insulators.

- Automotive components ranging from door and window seals to the charge air tubing for turbochargers.

As with many things, materials with great performance properties also have downsides. In the case of EPDM, getting the molded parts to release from the tooling/molds without reapplying mold release coatings every 2-4, or for some, every (molding) cycle. In continuous molding production, the more time spent reapplying mold release in between molding cycles is hurting production quantities.

Normally, Dyna-Tek’s mold sealers and release coatings typically are best suited to be applied to tooling/mold surfaces temperatures that are ambient (room) up to 35° C/95° F. However, we are pleased to introduce a new product line formulated so it can be applied while the mold is as high as 250° C/120° F.

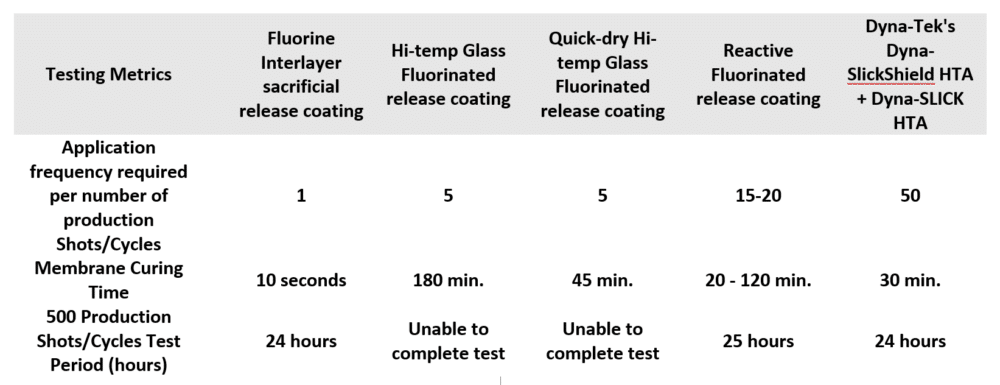

In comparison testing against legacy mold release products, Dyna-Tek’s products out-performed all products by significant margins as seen below:

For more information on Dyna-Tek’s rubber mold sealers and release coatings,

please email Info@Dyna-Tek.com or call us at 855-500-6266 and ask for Technical Support.

Leave A Comment